Event Summary: Designing Circular Solutions Across the Value Chain – Helsinki, 6.3.2025

Last week, nolla_E participated in the Designing Circular Solutions Across the Value Chain event in Helsinki. This event was part of the Nordic Circularity Piloting Program, which focuses on promoting circular economy solutions in technical building systems across the Nordic region. The program aims to pilot and develop new operational models that enable more efficient resource utilization, reduce carbon footprints, and support sustainable business practices. Through this initiative, companies can share their experiences and learn best practices for implementing circular economy principles in the construction industry.

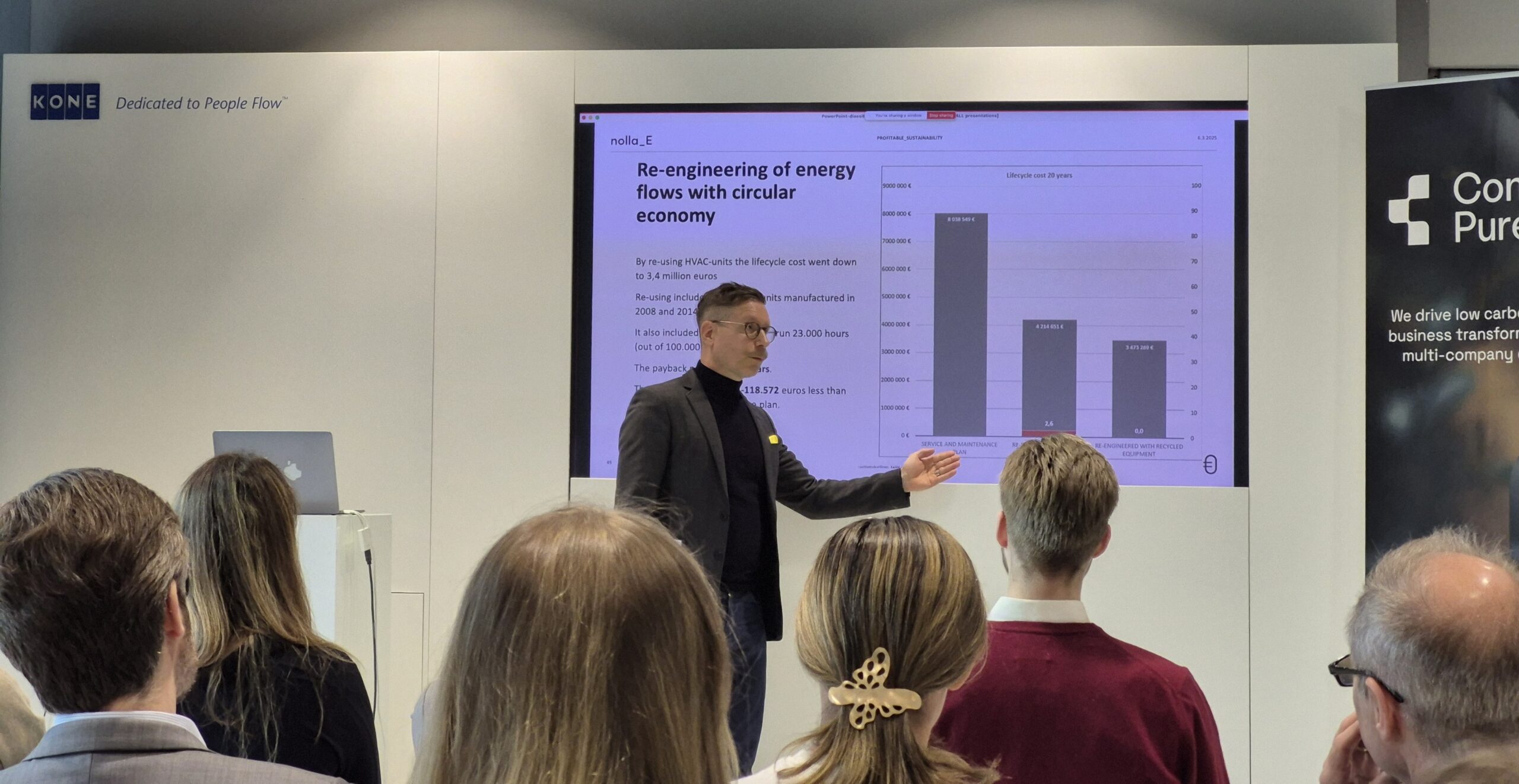

nolla_E’s Presentation: Circular Economy of HVAC Systems

nolla_E contributed to the event by sharing insights on circular economy practices in building technology. The presentation highlighted nolla_E’s approach to circularity, which includes comprehensive simulations that model both the building and its technical systems down to the component level. This allows cross-project analysis to identify surplus yet reusable equipment, enabling their repurposing in other locations. The presentation also featured a case study where circular economy solutions for building technology helped reduce costs significantly.

Combient Pure: Learnings from Previous Circular Economy Projects

Combient Pure shared key takeaways from past circular economy projects, emphasizing the importance of understanding customer needs and ensuring that pilot projects address real-world challenges. Measuring impact is crucial, with clear KPIs such as material savings, lifecycle extension, or CO2 reduction playing a significant role. Reverse logistics must be prioritized, and extending a product’s lifecycle through maintenance, refurbishment, and reuse is essential. Additionally, circular procurement requires aligning buyers’ and subcontractors’ processes, integrating circularity into the supply chain from the outset.

Skanska: Transforming Decision-Making in the Construction Process

Skanska’s representatives emphasized that shared responsibility, open and regular dialogue with partners, and early decision-making are key to successful circular construction. The company aims to integrate circularity at every stage of construction—from procurement to design and execution—leveraging data and digital tools to maximize impact. Proper material storage, carbon footprint assessments, sufficient time for circular processes, and tenant engagement can further enhance circular practices.

Talteka Project: Reusing Technical Building Equipment

Granlund’s expert presented the Finnish Talteka project, which pilots the reuse of technical building equipment. These pilots have identified challenges such as gaps in the value chain, lack of awareness, and regulatory complexities. The lessons learned will be compiled into guidelines to help stakeholders integrate circularity into technical building systems. Key insights include the importance of early decision-making, stakeholder collaboration throughout the process, and proper documentation of product and material information.

KONE: Cut Carbon Strategy

KONE’s new “Rise to Lead” strategy (2025–2030) focuses on sustainability and emission reductions. The company aims to help customers lower emissions through energy-efficient products and circular economy initiatives. KONE promotes circularity by extending elevator lifespans and piloting component reuse and refurbishment to minimize waste. The Replace with Retention modernization concept reduces CO2 emissions by up to 35%, shortens installation times, and minimizes operational disruptions compared to traditional replacement projects.

Digital Tools and AI as Enablers of Circularity

Digital tools are becoming increasingly essential for enabling circular economy practices. AI plays a significant role in managing change, supporting design, inventory management, and identifying reusable components—ultimately enhancing the feasibility of circular solutions.

Key Takeaways

The event highlighted several critical factors for advancing circularity:

- Considering circular economy principles from the design phase

- Engaging stakeholders early in the process

- Integrating cost and carbon footprint assessments into decision-making

- Leveraging AI and digital tools to support circular practices

- Commitment across the entire value chain and the importance of collaboration

The next session of the program will take place in Oslo on April 10, and remote participation is also available. Register for the Oslo event here.